FLYBOTIX is a young and dynamic startup, founded in Switzerland in 2019 that stands out in the development of compact industrial and commercial drones, especially focused on indoor inspections.

FLYBOTIX is known for innovative solutions that combine efficiency and safety in operations carried out in confined environments.

FLYBOTIX plans to expand its solutions and adapt its technologies to an even wider range of industrial and commercial applications.

IATEC Plant Solutions can share its vast experience in the application of UAVs through fast, efficient and safe inspections of industrial and commercial assets, in partnership with FLYBOTIX.

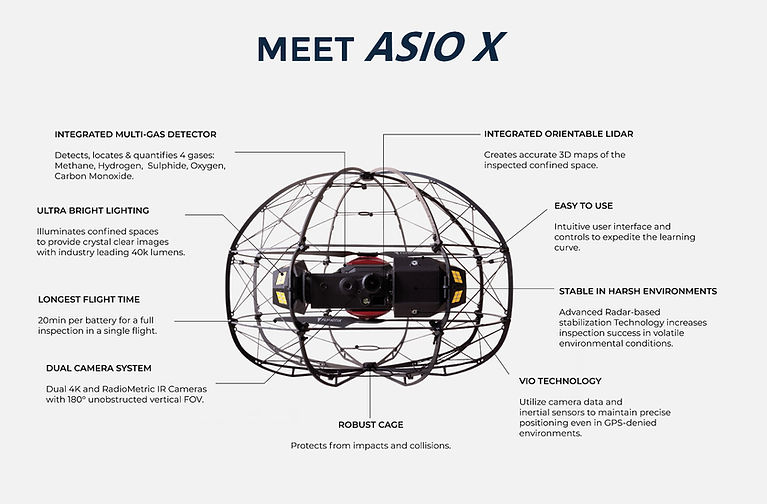

ASIO X

ASIO X combines innovation, efficiency and safety, being designed to operate in confined industrial environments, developed for indoor inspections.

ASIO X Drone - Simplified inspection process and quick decision making.

-

40K Lumens:

-

20 min Flight:

-

Gas Detector: H2S, CO, O2.

-

Easy to Pilot:

-

LiDAR Playload:

-

Robust Cage:

-

Stable:

-

AI Analytics:

FEATURES

-

Advanced Propulsion Technology:

-

Two Rotors: ASIO X uses a propulsion system with two rotors, which provides greater energy efficiency and flight stability in confined spaces, surpassing traditional four-rotor drones.

-

-

Navigation System and Sensors:

-

Autonomy and Accuracy: Equipped with advanced sensors, ASIO X can autonomously navigate complex environments, avoiding obstacles and collecting high-precision data, essential for detailed and safe inspections.

-

-

Robust and Compact Design:

-

Durability: Built to withstand challenging environments, ASIO X is resistant to collisions and impacts, ensuring safe and efficient operations in confined and difficult-to-access areas.

-

-

Practical Applications:

-

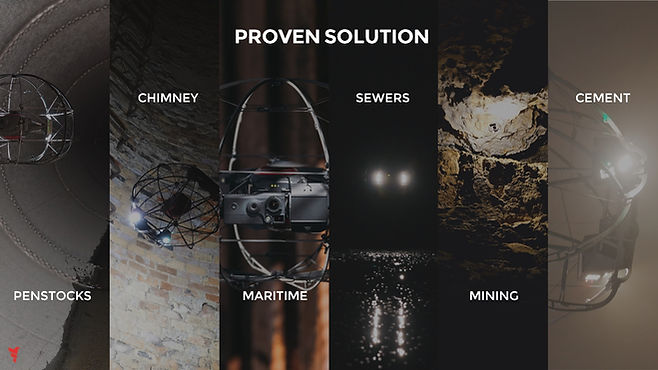

Internal Industrial Inspections: Ideal for inspections of tanks, chimneys, ducts and other internal structures where human access is dangerous or impractical;

-

Maintenance and Security: Helps identify potential problems in the infrastructure, allowing preventive maintenance to be carried out and increasing the security of operations.

-

APPLICATION

-

Internal Industrial Inspections:

-

Storage Tanks: ASIO X can inspect the interior of storage tanks without having to empty them, detecting corrosion, cracks and other structural defects;

-

Chimneys and Ducts: Ideal for checking the integrity of chimneys and ducts, identifying obstructions, corrosion and other irregularities that could compromise safe operation.

-

-

Preventive maintenance:

-

Equipment and Machines: Perform detailed inspections of industrial equipment, such as turbines and generators, allowing early detection of failures and performance of preventive maintenance;

-

Factory Structures: Inspects beams, ceilings and other internal structures of factories, guaranteeing the safety and longevity of the facilities.

-

-

Security and Compliance:

-

Hazardous Environments: Perform inspections in dangerous or difficult-to-access areas, reducing risk to workers and ensuring compliance with safety standards and industrial regulations;

-

Continuous Monitoring: Can be used for continuous monitoring of critical facilities, providing real-time data on the status of structures and equipment.

-

-

Infrastructure inspection:

-

Power Plants: Inspects internal components of power plants, such as turbines and boilers, without having to turn off the equipment, increasing operational efficiency;

-

Processing Facilities: Verifies the integrity of processing facilities, such as refineries and chemical plants, ensuring safety and compliance with industry standards.

-

-

Fault and anomaly detection:

-

Defect Identification: Uses advanced sensors to detect cracks, corrosion, leaks and other anomalies in internal structures;

-

Detailed Reports: Generates detailed reports with accurate data and high-resolution images, helping you make informed decisions about repairs and maintenance.

-

TECHNICAL SPECIFICATIONS

-

Weight: approximately 1.1 kg;

-

Diameter: approximately 400mm;

-

Height: approximately 300mm;

-

Number of propellers: 2 (coaxial design);

-

Motor: brushless electric motors;

-

Battery: LiPo (Lithium Polymer);

-

Flight time: approximately 20 min;

-

Max speed:

-

Assisted: 1 m/s (3.2 ft/s);

-

Manual: 5 m/s (23 ft/s).

-

-

Main camera: 4K UHD for high-quality video recording;

-

Max luminosity: 40,000 lumen;

-

Additional sensors: Distance sensors for navigation in narrow spaces;

-

Control: radio frequency remote control;

-

Communication range: up to 500 m in an open environment;

-

Data storage: onboard SD card (FAT32 format);

-

Sensors:

-

IMUs ( 1 High-grade + 1 fallback);

-

Magnetometer;

-

Barometer;

-

Distance sensors;

-

Optical flow sensors;

-

Radar;

-

Global shutter cameras (VIO).

-

*SELF-SERVICE store is for BRAZIL clients only. US clients must contact us through contact@iatecps.com for pricing and delivery conditions.